In many ways, the war between Ukraine and Russia has evolved into a contest of who has the longest stick.

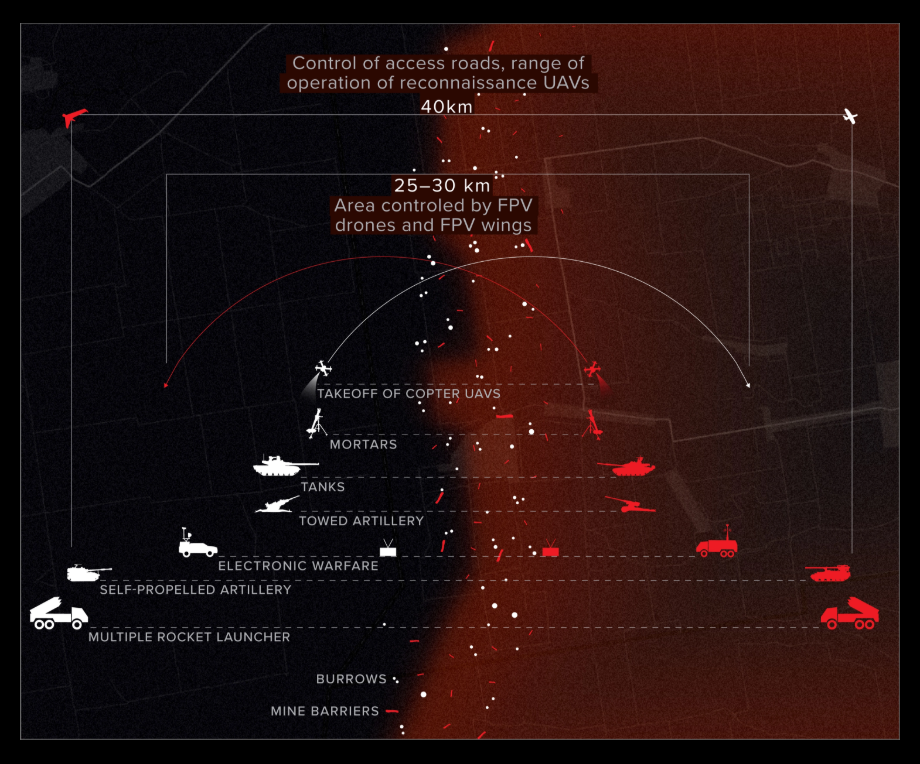

Thanks to drones and glide bombs, the no-man’s land between opposing forces, once measured in hundreds of meters, has swelled to kilometers. Each side has been working on ways to extend their strike range, primarily through improving control methods and also battery life.

Now, Ukrainian drone battery manufacturer Pawell Power says it’s discovered a way to nearly double battery efficiency at the same weight. This allows drones to either fly much farther, extend their loiter time, or allow them to mount heavier payloads.

This, in turn, enables greater tactical flexibility in the field for Ukrainian troops. Operators can potentially kill the bad guys from farther away, do more damage against targets, or perform lengthier reconnaissance or overwatch of a mission area. Depending on how this tech is used, this may enlarge the gray zone yet again and push it in the Russians’ direction.

According to the company’s prior statements, certain drones that once managed 3-5 km can now reliably do 15-30 km, a five-to-sixfold increase.

The current record that FPV drones equipped with their "Vampir" batteries have managed is 38 km and the company is looking to extend that to 60.

Euromaidan Press spoke with the founder, Pavlo Esyp, who said their tech is already in the field. The company currently supplies enough batteries to drone units to cover over 80% of the needs of the entire Zaporizhzhia Front.

“We are proud of our latest development,” Esyp said. "We're especially happy in those moments when the guys drop feedback and say 'wow, cool, send us another, send us another' because it assures us of their effectiveness. This feedback motivates us."

The trick was to fuse the capabilities of solid-state power cells with high-current Lithium-ion batteries and 3D printing impact-resistant polymer casings, which could also protect from heat. This innovation has raised battery efficiency by 77% without increasing their weight. The batteries also come with a feedback system that tells the pilot how much charge remains available.

The other advantage is, the company's batteries are highly modular, meaning they can be built to accommodate a variety of different drone types, from the smaller FPVs, to the heavier bombers, such as the model the Russians have taken to calling “Baba Yaga” after the infamous witch of Slavic folklore.

"We are constantly working with [drone] developers to find optimal physical dimensions for our power supplies that can easily integrate," Esyp said. "Modifying the frame or the output cable is a matter of hours, not weeks. Our internal flexibility allows us to quickly create variations to accommodate the specific demands of our customers."

Better yet, Esyp said that all the materials used to build these batteries are commonly available on the open market.

Of course, batteries aren’t the only factor that influences drone performance. The range and reliability of the control system is hugely important, and is being worked on by multiple Ukrainian developers. Battlefield conditions are important as well.

“It often happens that the very limitation of this range is dependent on the specific location, which is influenced by electronic countermeasures, geometry, and the terrain, whether there are hills,” Esyp said. “In other words, it's a multifaceted factor that influences results.”

Esyp has been conducting R&D into various types of technologies, including 3D printing since 2016. When the full-scale invasion began, he said his main focus was to use his primary expertise to bring the most value possible to the Armed Forces of Ukraine. He's also motivated by his two sons, for whom he wants to secure a brighter future.

He and his colleagues began their work in 2022 before officially founding the company that same year, when demand for drone power supplies began increasing. In 2023, the company got UAH 2.2 million ($53,000) in grants from the Brave1 defense cluster.

Their latest advancement with the batteries came in 2025, but Esyp wouldn't call it a “breakthrough” per se. According to him, there was never one Eureka moment, only a process of small, incremental improvements over years.

“We gradually tried different approaches to welding, connecting elements, using cables, and using different types of metal,” he said.

“There wasn't a sudden, ‘wow’ moment, and then this product was ready the next day. These are the kind where a lot of small improvements have a cumulative effect, and now it looks like a breakthrough. This breakthrough is the result of many small steps and improvements we've made up until now.”

On top of improving this technology, the company is also looking into batteries that can discharge their capacity in a very short time. This is necessary to power interceptor drones, which have to accelerate to their top speed of hundreds of kilometers per hour extremely quickly, and have very hungry energy requirements as a result.

Such interceptors are a rising star in Ukraine’s drone warfare doctrine, often tasked with hunting enemy UAVs, from long-range strike units, to reconnaissance and observation models.

Pawell Power also wants to apply its batteries to unmanned ground vehicles, which also represent a growing trend in the drone war, as Ukrainians try to compensate for their manpower shortage with remote-controlled or robotic alternatives.

In terms of business growth, the company has several key priorities. Like most Ukrainian defense contractors, Pawell Power is not working at the full capacity it’s capable of, due to the limited availability of procurement funding.

“I generally think that investments into the company would be a huge plus,” Esyp said. “It would enhance the company's capabilities.

“At the same time, I think that investing solely in terms of funds is limiting. When it comes to investments, it would be great if it weren't just money, but also experience, insights, access to markets, perhaps a merger, perhaps a buyout, collaboration with other drone manufacturers, but not solely, exclusively, money itself as a tool.”

The other priority is expanding R&D and automation, to be able to build on their existing strengths.

“We're currently working on automating our production. This is the focus of our development. Automation and increasing throughput, further simplifying processes to make production easier,” Esyp said.

“It would be great if we could further expand our R&D department, work on promising developments that could yield results in, say, six months, because just because a solution works now doesn't mean it will work in six months or a year.”

“The situation is changing rapidly, and focusing only on what we have now is likely a losing strategy.”